Why Improvise

Individual and Mentorship

Design & Manufacturing

Jun 2021

Beyond the physical product made, this project taught me the importance of roadblocks. The project started in school when I was assigned to do an In-Depth study on a skill of my choice. The first topic that appealed to me was woodworking; it felt like a must-have in any creative's toolbox.

With little experience and safety knowledge in the subject, I sought out a mentor. I am still thankful for Mr. Ross who lent me his expertise and patience throughout this project. Together, we decided to create a birdhouse as it was a fairly approachable beginner project many start off with, but to our surprise, a simple birdhouse can pose a sea of challenges.

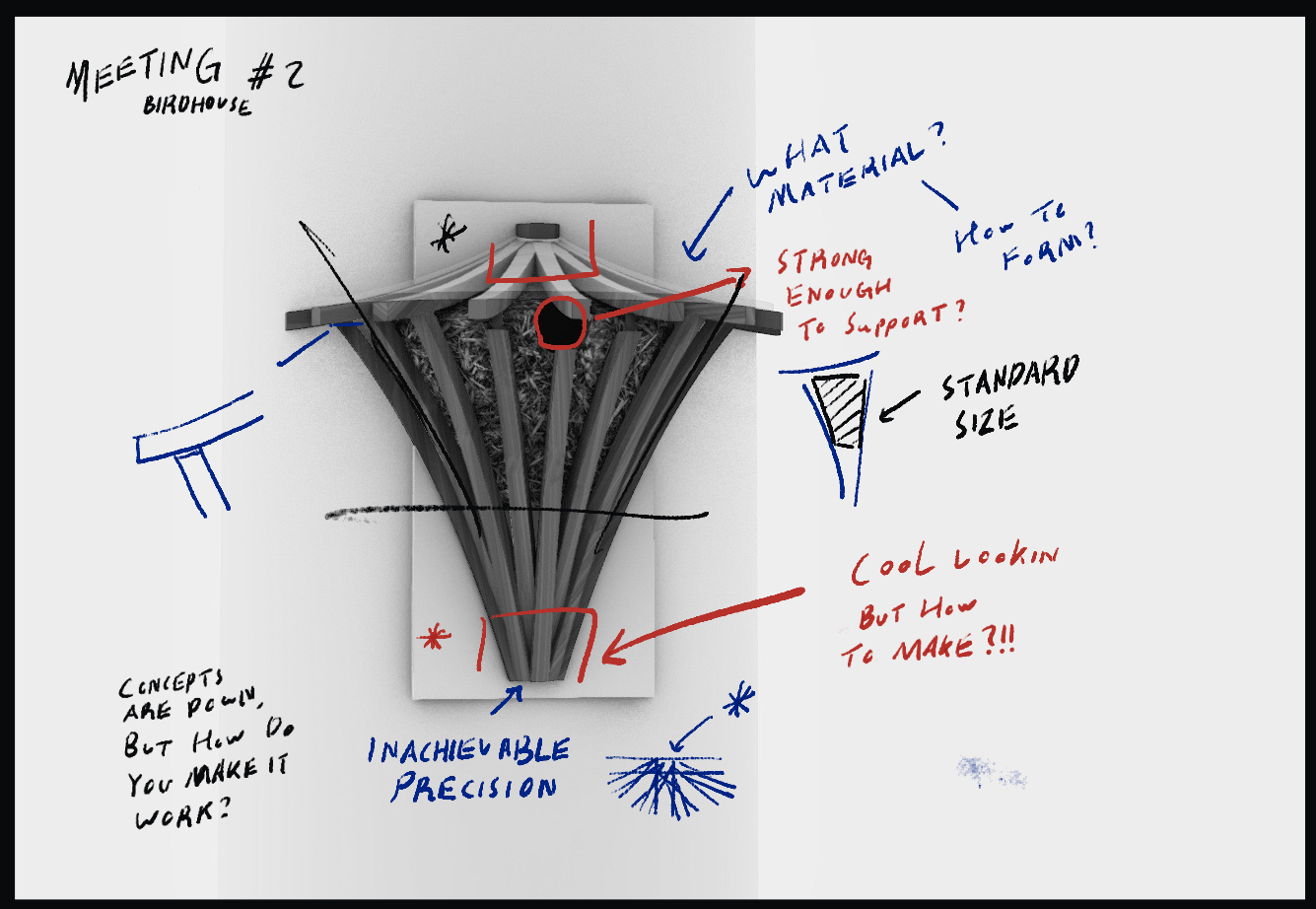

Meeting notes with mentor - flaws with inital parti | Forest walk - field study

One of the first problems that arose regarded the initial parti. Inspired by fungi I observed during a hike, my proposal aimed to blend the birdhouse into nature by adopting a natural form. The design looked amazing on paper, but when it came to manufacturing it, the issues quickly became apparent. Due to technological limitations, it was clear that the original design couldn’t be cooked up in a garage, and because of this, we had to change gears.

Lesson #1

“Know when to stop chasing a girl that dosn’t love you back” i.e. don’t become impossibly attached to impossible ideas

We tried to solve the problems in our heads and on paper, creating drawings and fancy computer models. However, the more we thought the more impossibly confusing this project became. This was our calling to get our hands dirty.

Lesson #2

“Can’t love a gal if she ain’t real” i.e. you can only visualize so much in your head.

We then fabricated a prototype which unveiled new, wildly creative solutions through a tangible object. The more I’d look, I'd get more comfortable with the problems that arose. When revisiting these issues, these problems even looked like opportunities.

Lesson #3

“When things aren’t working, try giving some space” i.e. value the importance of a fresh perspective

Adapting to challenges with original design - Concrete mixed with straw for cradle.

Adapting to challenges with original design - Resin and pine leaf on heavy paper roofing.

The problems forced us to be creative and resourceful. We scavenged the garage for what we could use to make the form come together. Resin and pine leaves formed the roof, concrete mixed with straw created the cradle, cast Paris bandage reinfoced the cradle, and bent wood lamination formed the support beams. These new solutions resulted from the challenges we faced. Looking back, the adaptations revealed a far more beautiful design than the original.

Lesson #4

“Your perfect gal probably isn’t your magazine cover” i.e. flawless things lack character

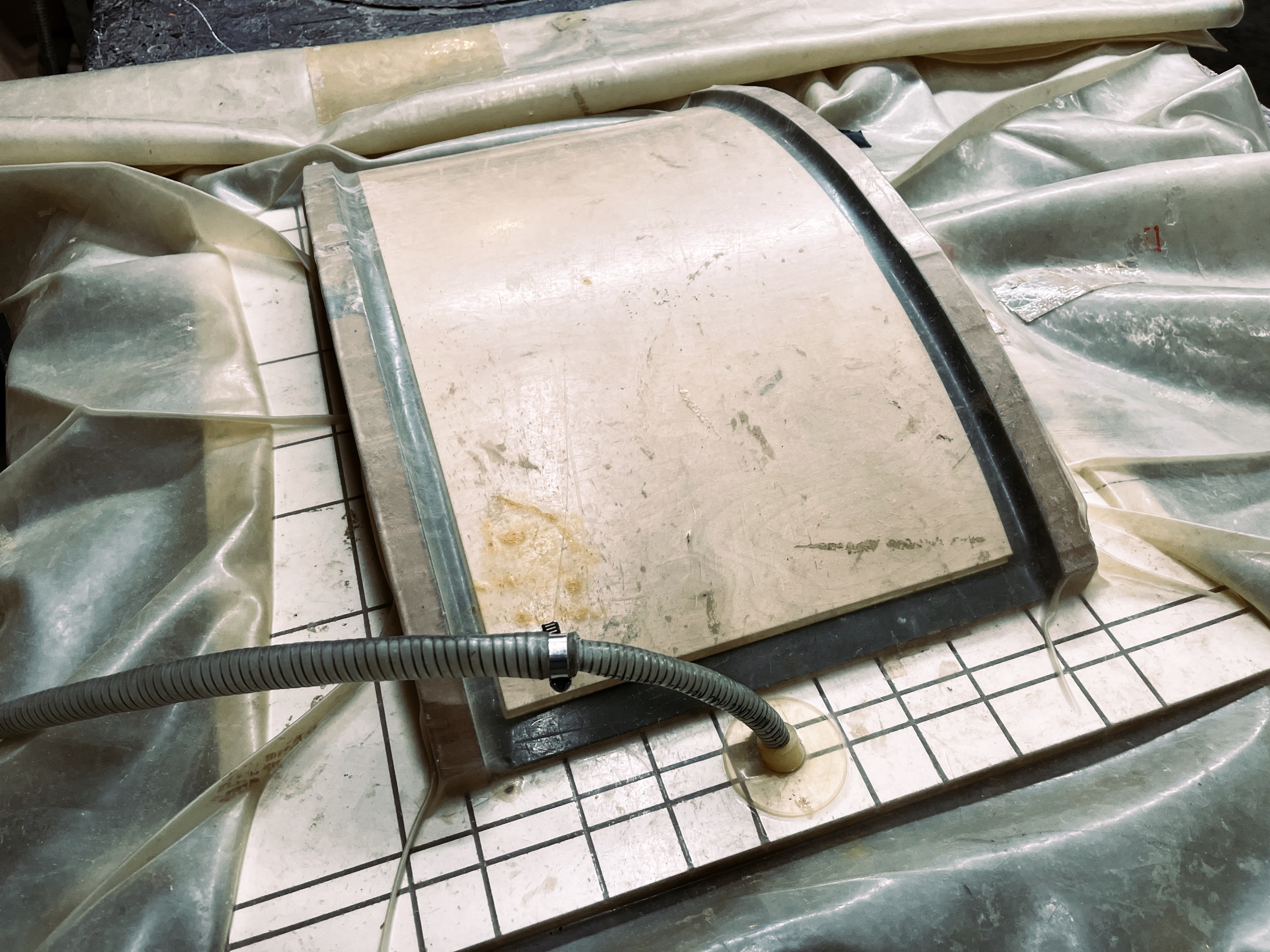

Bent wood lamination stage 1 - Placing baseboard.

Bent wood lamination stage 2 - Installing cast with desired arch.

Bent wood lamination stage 3 - Vacumming wood onto installed cast.

This project bombarded us with roadblocks since the very start of this, but through improvising, we found personality. By operating on the edge, we were forced to get creative and consider solutions that were invisible in the perfect plan. Now ask yourself, is the perfect path always the most beautiful path? I'm not sure, but this project has proven to me that there may be something worth discovering if you’re willing to drift off a little.

Humongous thanks to my mentor

Mr. Ross

Mr. Ross

Special-Special-Special thanks to my organizer

Ms. Mulder

Ms. Mulder